Xem thông số kỹ thuật để biết chi tiết sản phẩm.

NDT2955

Product Overview

Category: Semiconductor

Use: Power MOSFET

Characteristics: High voltage, low on-resistance

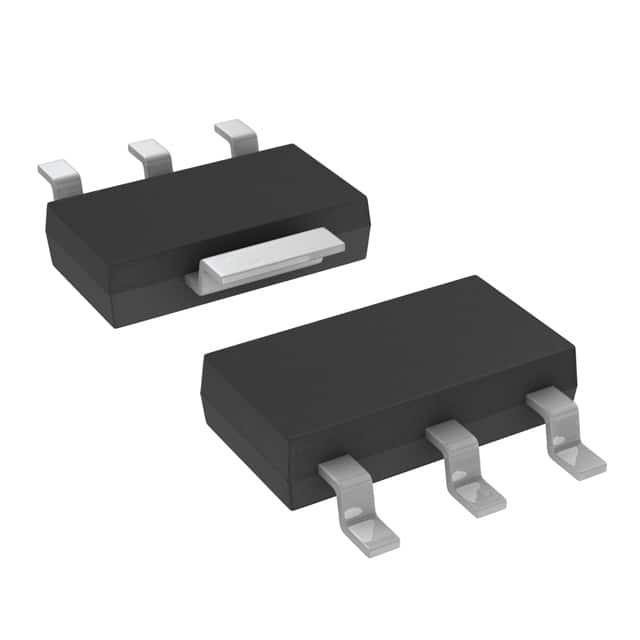

Package: TO-252, TO-220, D2PAK

Essence: N-channel enhancement mode power field-effect transistor

Packaging/Quantity: Reel/1000 units

Specifications

- Voltage Rating: 60V

- Continuous Drain Current: 11A

- RDS(ON): 0.025Ω

- Gate Threshold Voltage: 1-2V

- Power Dissipation: 2.3W

Detailed Pin Configuration

- Gate (G)

- Drain (D)

- Source (S)

Functional Features

- Low gate charge

- Fast switching speed

- Avalanche energy specified

- Improved dv/dt capability

Advantages and Disadvantages

Advantages: - Low on-resistance - High voltage rating - Fast switching speed

Disadvantages: - Higher gate threshold voltage compared to some alternatives

Working Principles

The NDT2955 operates based on the principle of controlling the flow of current between the drain and source terminals using the voltage applied to the gate terminal. When a sufficient voltage is applied to the gate, it creates an electric field that allows current to flow between the drain and source.

Detailed Application Field Plans

The NDT2955 is commonly used in various power management applications such as: - Switching power supplies - DC-DC converters - Motor control - LED lighting

Detailed and Complete Alternative Models

Some alternative models to NDT2955 include: - IRF3205 - FQP30N06L - IRL540

This completes the entry for NDT2955, providing comprehensive information about its category, use, characteristics, package, specifications, pin configuration, functional features, advantages and disadvantages, working principles, detailed application field plans, and alternative models.

Liệt kê 10 câu hỏi và câu trả lời thường gặp liên quan đến ứng dụng NDT2955 trong giải pháp kỹ thuật

What is NDT2955?

- NDT2955 is a type of non-destructive testing (NDT) method used to inspect and evaluate the integrity of materials or components without causing damage.

How does NDT2955 work?

- NDT2955 typically involves using electromagnetic or ultrasonic waves to detect flaws, cracks, or irregularities in materials by analyzing their response to these waves.

What are the advantages of using NDT2955?

- NDT2955 allows for the inspection of materials without causing damage, provides accurate results, and can be used on a wide range of materials and components.

In what technical solutions is NDT2955 commonly applied?

- NDT2955 is commonly used in industries such as aerospace, automotive, manufacturing, and construction for inspecting welds, pipelines, structural components, and composite materials.

Are there any limitations to NDT2955?

- While NDT2955 is effective for detecting surface and subsurface defects, it may not be suitable for very thin materials or highly irregular surfaces.

What equipment is needed for NDT2955 inspections?

- Equipment for NDT2955 inspections may include ultrasonic testing instruments, eddy current testing devices, magnetic particle inspection tools, and visual inspection aids.

What are the safety considerations when performing NDT2955 inspections?

- Safety considerations include ensuring proper training for personnel, using appropriate personal protective equipment, and following established procedures to minimize potential hazards.

Can NDT2955 be used for quality control purposes?

- Yes, NDT2955 is often used for quality control to ensure that materials and components meet specified standards and do not have defects that could compromise their performance.

What are some common indications found through NDT2955 inspections?

- Common indications include cracks, voids, inclusions, delaminations, corrosion, and other anomalies that could affect the structural integrity of the material or component.

How does NDT2955 contribute to cost savings in technical solutions?

- By identifying defects early in the production or maintenance process, NDT2955 helps prevent costly failures, reduces rework, and extends the lifespan of materials and components.